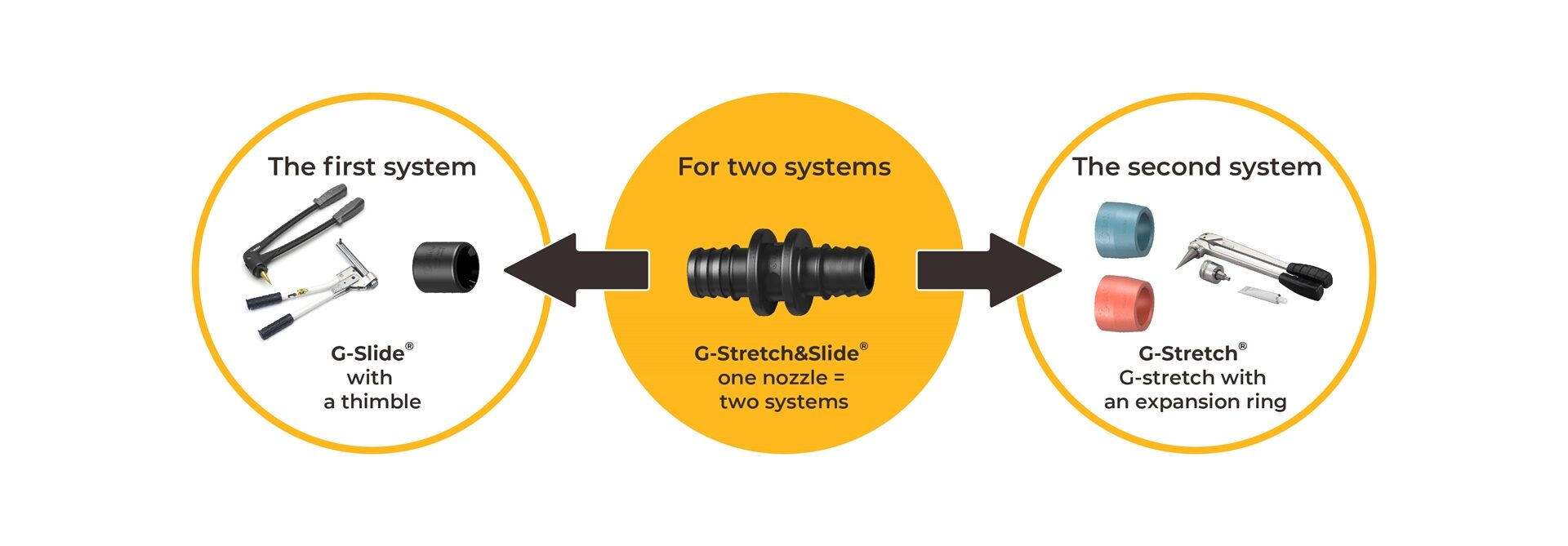

How to create the reliable universal nozzle for two systems?

We created the new type of G-Stretch&Slide fittings with universal nozzles and special stops for tools. As a result, our fittings are used with two types of completely different, top ranking pipeline systems with “Thimble” and “Expansion ring”.

For the “moving system”, we use supporting dielectric material!

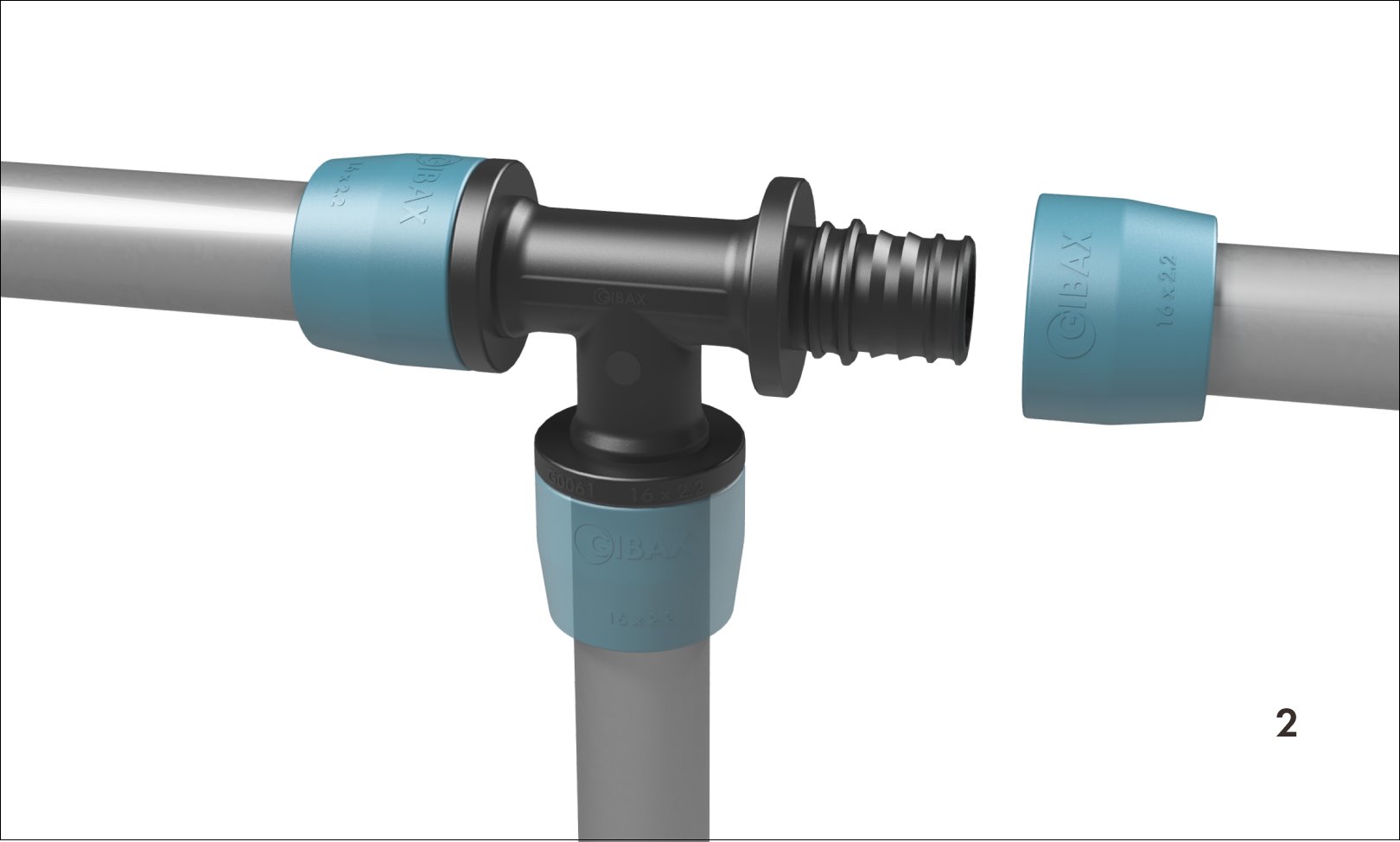

For the system with “expansion ring”, we use the carrier brush!

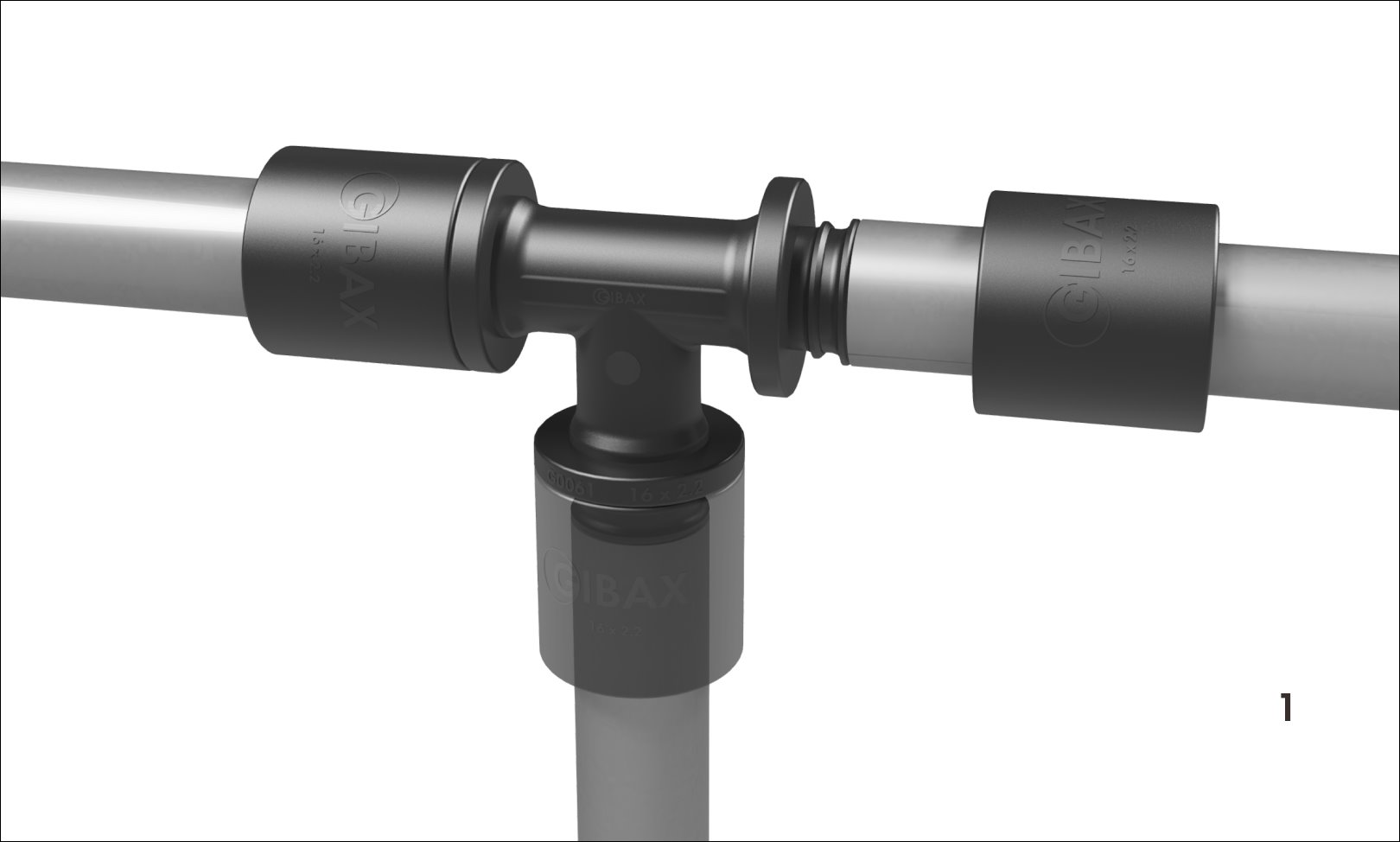

The unique design of nozzles made of PPSU polymers, bronze or brass has a special configuration of brushes for axial systems with “Thimbles”, including a certain oversized brush (ref. 1) which prevents the aluminum layer of the metal-reinforced plastic pipe (ref. 2) from touching the body of the bronze fitting, thus it acts as dielectric material. In the axial system with “Expansion rings”, this brush/dielectric acts as the main brush (ref. 3) which ensures the connection tightness.

The first system relies on the thimble!

The thimble is made of PVDF/polyvinylidenfluoride, it has increased elasticity, thermal resistance from — 40°C to + 140°C. It has all necessary goods in order to ensure the hermetically-sealed connection and service life for more than 50 years. This and small friction when moving the thimble provided by the smooth inner surface of the thimble, and high density of PVDF, which as clamps clasps the pipe together with the nozzle, subjecting to constant clasping strain thanks to increased elasticity of PVDF compensate temperature drops, mitigate compression and expansion, thus excluding smudges and leakages. To connect, two tools are required: expansion and slip tools.

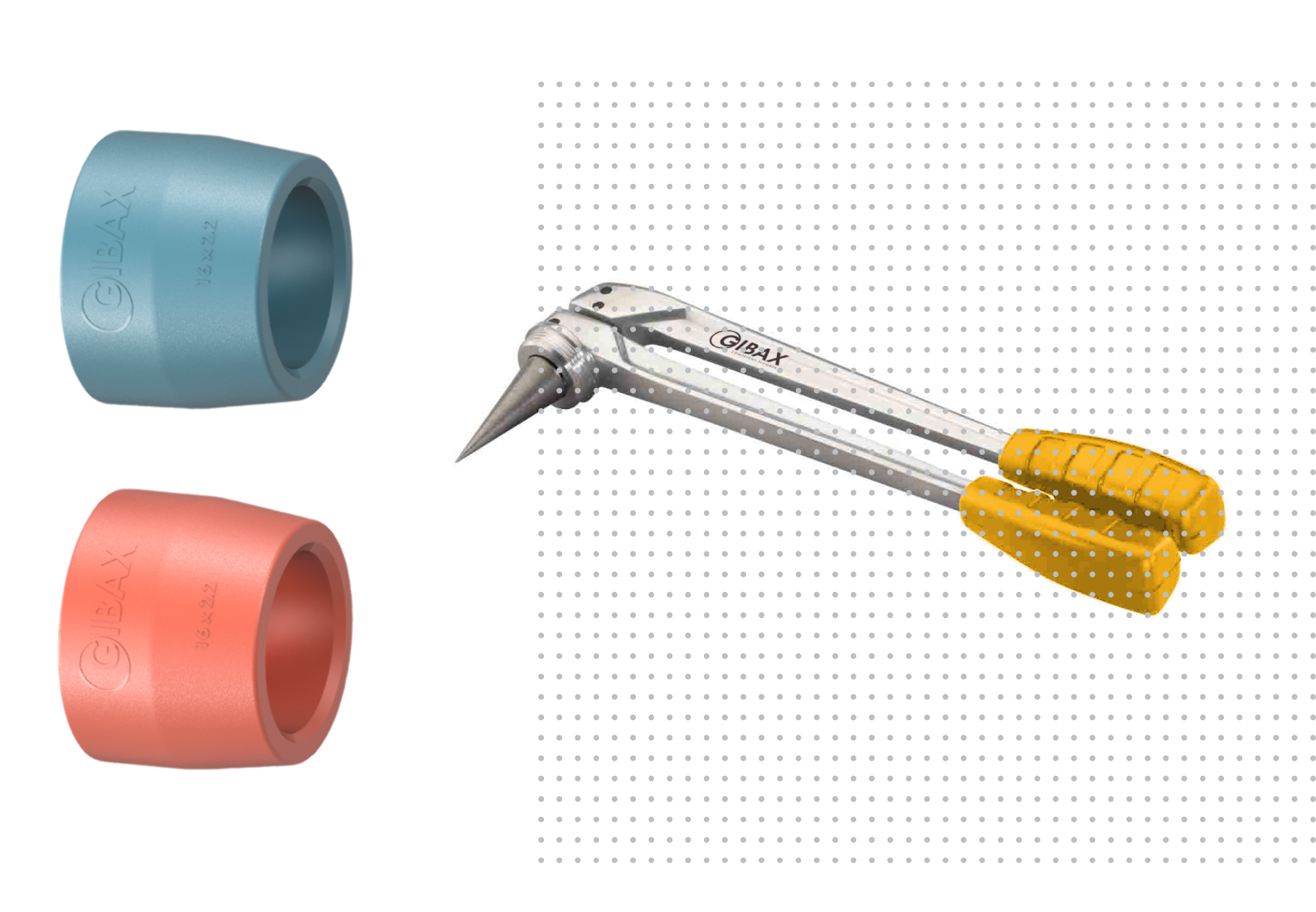

The second system relies on the expansion ring.

The expansion ring made of PE/cross-linked polyethylene has the outstanding memory and tries to restore its initial shape afer expansing the pipe together with the expansion ring; 20 minutes after, the pipe together with the expansion ring will restore its initial shape and tightly clasps the nozzle, compensating temperature drops, mitigating compression and expansion, thus excluding smudges and leakages. To connect, one tool is required: expansion tool.

2-FOLD SAVING of stock reserves.

Assembly tools from other manufacturers are suitable.