These pipes have a perfect memory!

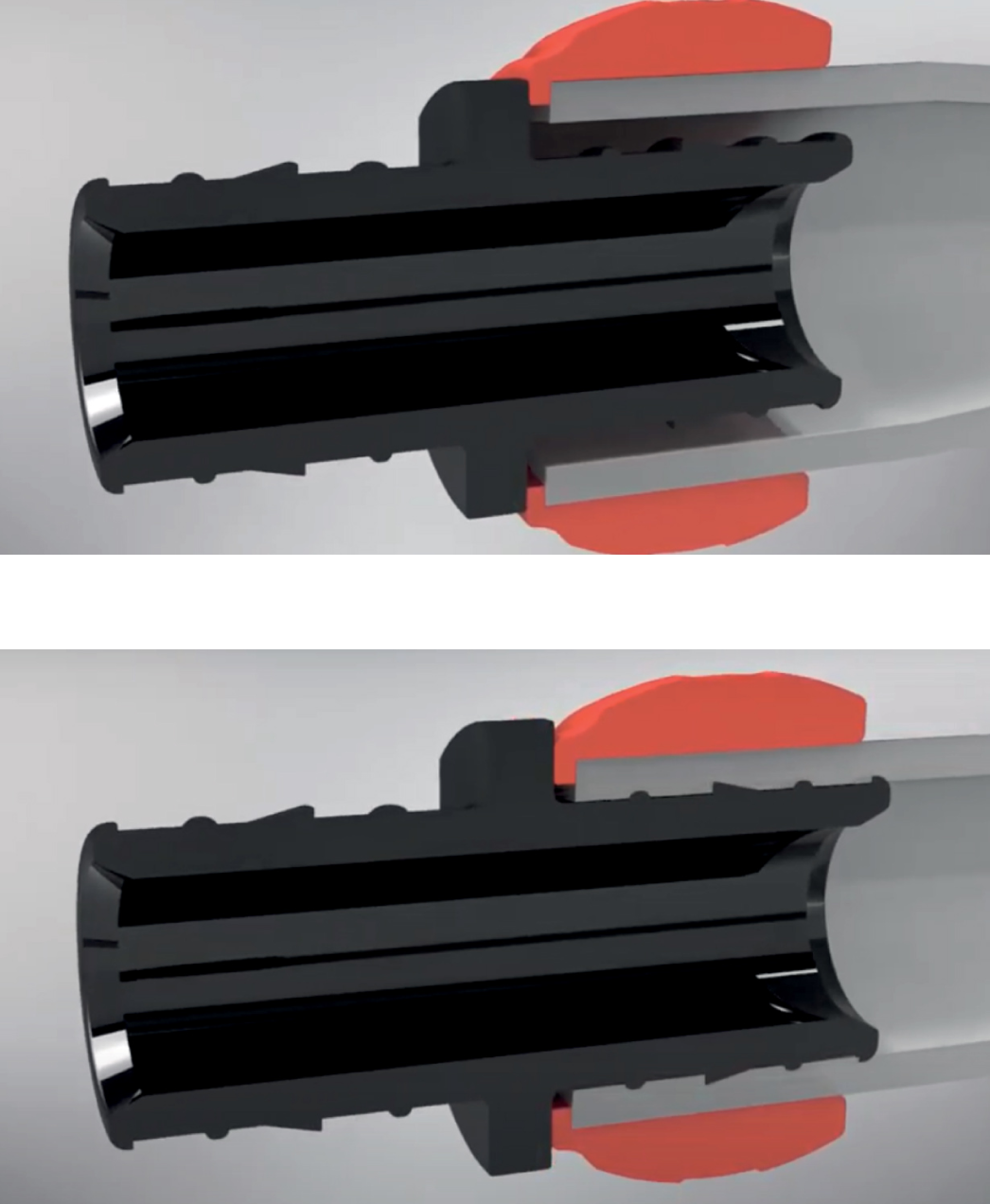

Pipes made of cross-linked polyethylene PE-Xa have unique properties – this is called the memory effect when after expansion the pipe very quickly restore its initial form.

For more about PE-Xa

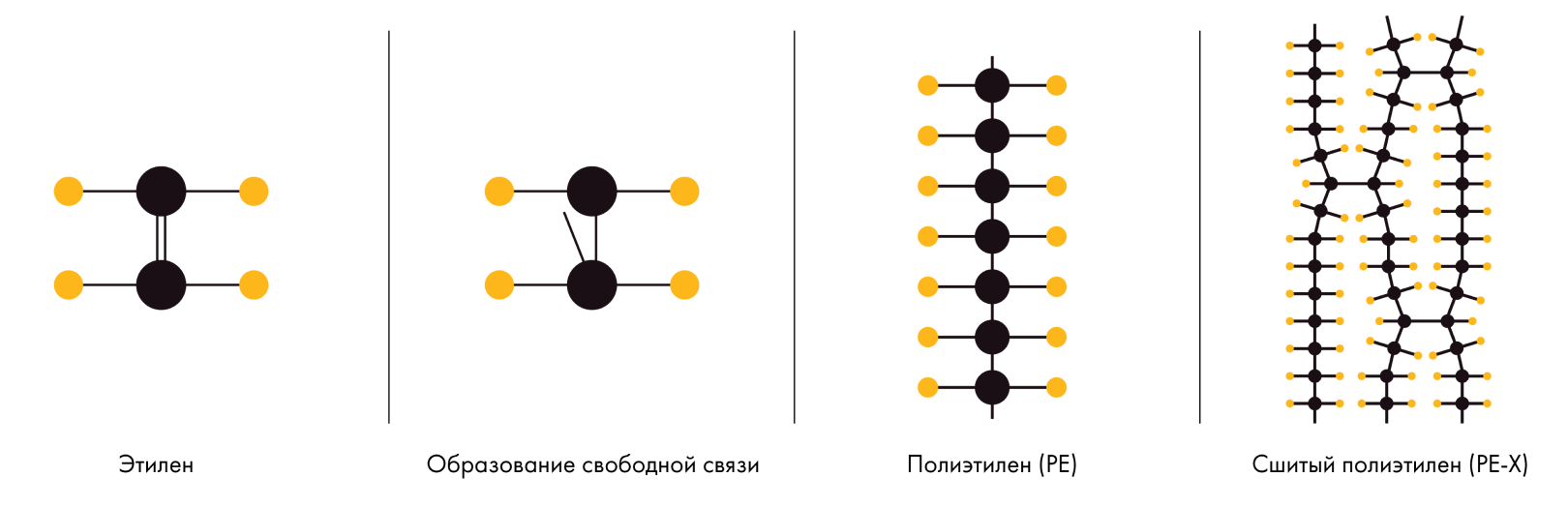

Polyethylene linked by means of peroxides is designated as PE-Xa. The given type of cross-link takes place at high temperature and high pressure with the use of peroxides. In such a case, individual molecular chains of polyethylene are combined into a single three-dimensional structure. Cross-linking at high pressure is characterized by conducting the melting process, i. e. above crystallization point. Cross-linking process takes place in the extruder during formation of the pipe and ensures the uniformly high percent of cross-linking throughout its cross section, even for heavy-wall pipes. Using this method, the minimum acceptable value of the cross-link yield is 70%

Without gaskets and seal glands

In connections of such pipes with fittings, gaskets and seal glands are not used too, because the pipe itself is a sealing material, as a result such connections are more reliable and long-life and free of maintenance during the entire service life.

Bends don’t mean a thing

Thanks to the memory effect, it is possible to restore the bend places using the hot air gun. In this case, non-cross-linked pipes begin to melt. The memory effect prevents material melting under pressure. This is huge plus for interconnection technology. Cross-linked polyethylene for manufacturing PE-X pipes keeps up the shape under tension as well.